Capability

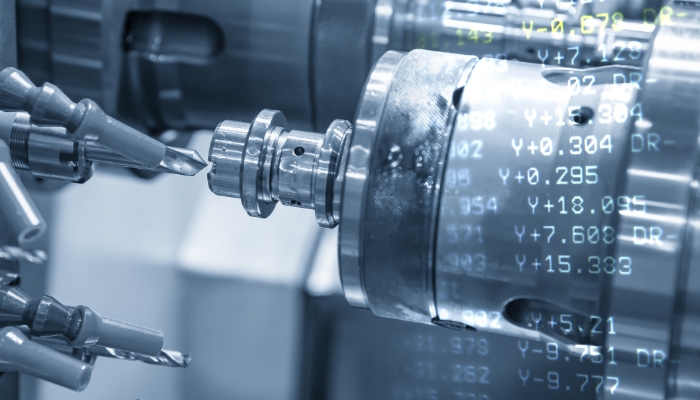

Our comprehensive and dependable development team can match surface treatment and machine processing based on customer requirements and precision settings as well as the different properties of processed materials to meet the requirements of various parts. Our products have been praised by our partners and we continue to improve in order to satisfy customer’s expectations and grow with them.

Processing Materials:

Aluminum: AL2011, AL2017, AL2024, AL6061, AL6063, AL6082, AL6463, AL7005, AL7075

Stainless Steel: SUS303, SUS304, SUS316, SUS416, SUS430, SUS630

Iron: 1144, 1215, 12L14, S15C, S45C, SCM415, SCM420, SCM435, SCM440, SNCM220, SUJ2

Others: Brass, Red Copper, POM, Ti-6Al-4V

For years, we have spared no efforts in our requirements for precision parts. We meet customer’s expectations towards products and Yung Cheng Shun through our production capabilities and the optimization and control of processes to grasp conditions of all employees and machinery at every phase. Currently, our company’s production lines have broadly implemented Japanese turret-type CNC lathes capable of turning, milling, drilling, boring, and tapping to complete precision processing with a single machine.

| 1. |

CITIZEN SWISS-TYPE CNC LATHES Diameter range of turning Ø2~Ø32mm |

34 SETS |

| 2. |

WASINO TURRET-TYPE CNC LATHES Diameter range of turning Ø10~Ø60mm |

5 SETS |

| 3. |

MIYANO TURRET-TYPE CNC LATHES Diameter range of turning Ø10~Ø51mm |

15 SETS |

| 4. |

MAZAK TURRET-TYPE CNC LATHES Diameter range of turning Ø10~Ø32mm |

1 SETS |

| 5. |

NAKAMURA-WY-100 Turret Type Multitasking Machine Diameter range of turning Ø10~Ø51mm |

1 SETS |

In order to provide customers with improved services, Yung Cheng Shun imported turret-type CNC lathes from Japan, tens of composite turning and milling processing machines, automatic 3D imaging instruments, and various precision equipment to maintain product quality. While optimizing our CNC processes and stability of our quality, we have also introduced advanced CAM software to increase production efficiency and deliver both products and services that satisfy customers. Yung Cheng Shun possesses the equipment and capabilities that allow us to easily achieve the processed parts requirements for customers in all industries. For example: parts for remote controlled cars, small parts inside car shock absorbers, small processed parts in motorcycle shock absorbers, small processed parts in scooter shock absorbers, small parts in car braking systems, transmission systems, medical parts, electronic ports, valve oil seals, various automotive circuit connectors, connecting rods, small processed parts for disc brakes, pistons, small processed parts for car steering systems.

For many years, Yung Cheng Shun has spared no efforts towards the requirements of precision hardware parts by providing customers with hardware processing services that meet their demands. Main materials in hardware parts processing include: materials such as stainless steel and aluminum alloy with surface treatments that enhance product strength and durability, such as: anodizing, baking paint, applying anti-rust oil, heat treatments, and more. Currently, our company’s production line has widely adopted Japanese turret-type CNC lathes capable of turning, milling, drilling, boring, and tapping to complete precision processing with a single machine. If you need OEM hardware parts, please contact us!