About Us

About Yung Cheng Shun

Yung Cheng Shun Industry Co., Ltd has invested many years in precision turning and processing of CNC composite parts, automatic lathe processing, and CNC milling processing to produce parts that are broadly applied in industries such as bicycles, cars, electronics, hardware, and handheld tools. Our production technology has continued to improve in order to service customers with all-rounded services and high quality prices while maintaining competitive pricing and fast delivery. Our various lathes and precision testing instruments are continually expanding to satisfy customer requirements and our principles in R&D and innovation achieves the most premium processed metallic and non-metallic parts. Yung Cheng Shun focuses on product quality, employee management, and training to offer our customers the best services.

Company History

Operational Policy

In order to provide the best CNC lathe processing, turning and milling composite processed products, and satisfy our customers’ requirements, Yung Cheng Shun has continued to upgrade and refresh the company over the past 3 decades to grow with our customers and meet their expectations. The company has invested heavily into the most advanced production and testing equipment using the principles of sustainable operations to pass ISO certifications. Our efforts will undoubtedly provide customers with better CNC lathe processing and turning and milling composite processing services to satisfy the high-precision processing requirements of the future.

Quality Policy

Customer First, Prioritize Efficiency, Top Quality

We believe that “products speak for themselves”. The only way to winning a customer’s trust is producing excellent, high quality products.

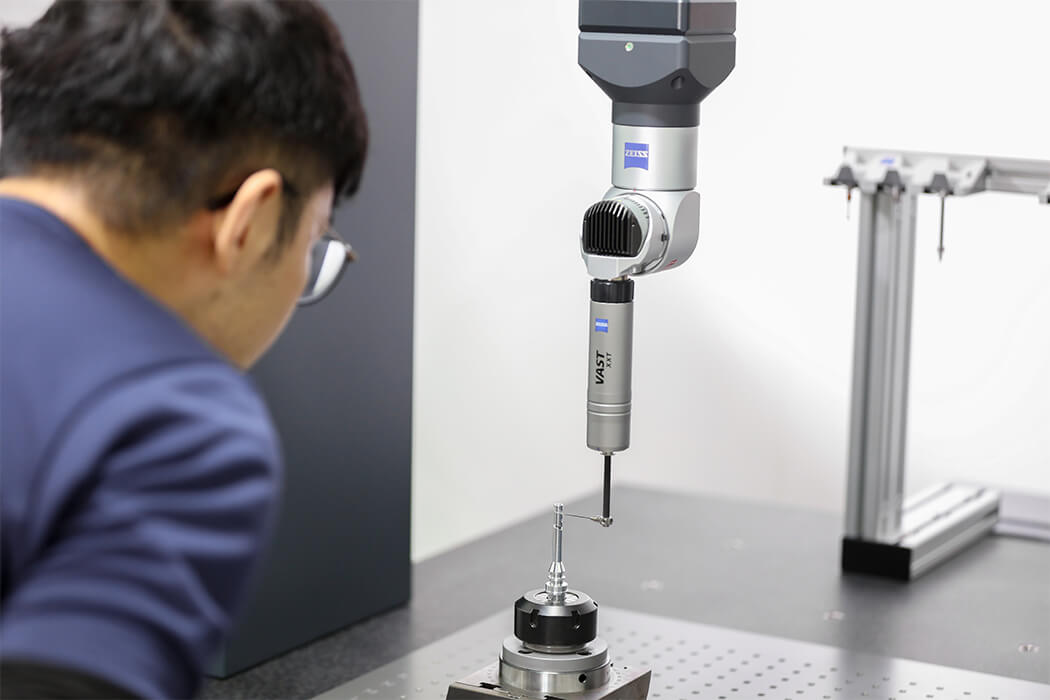

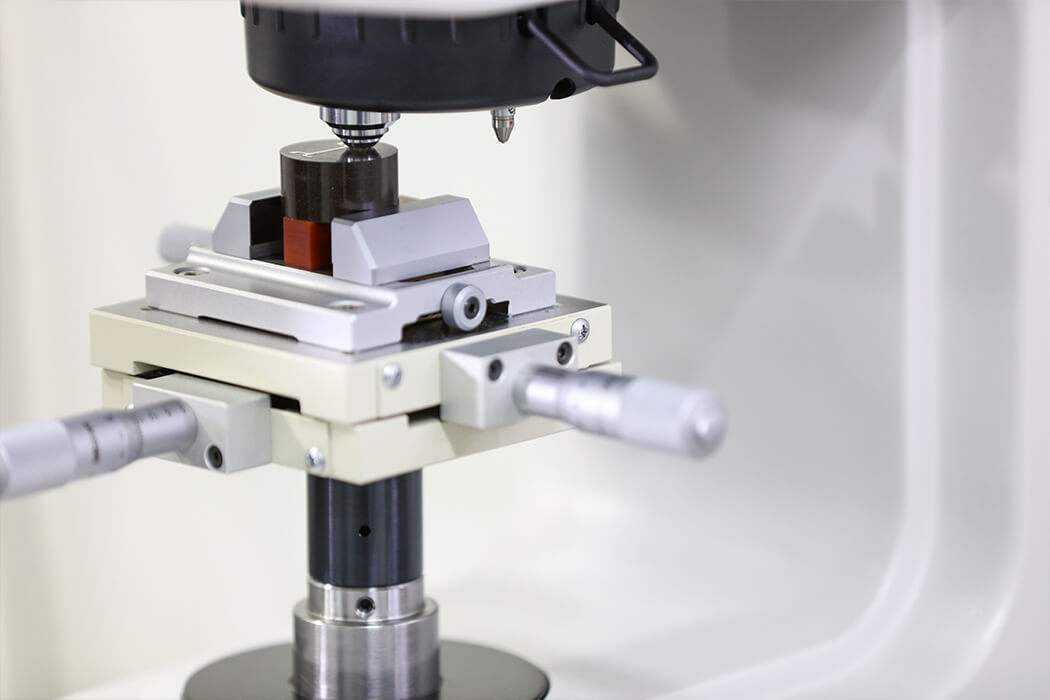

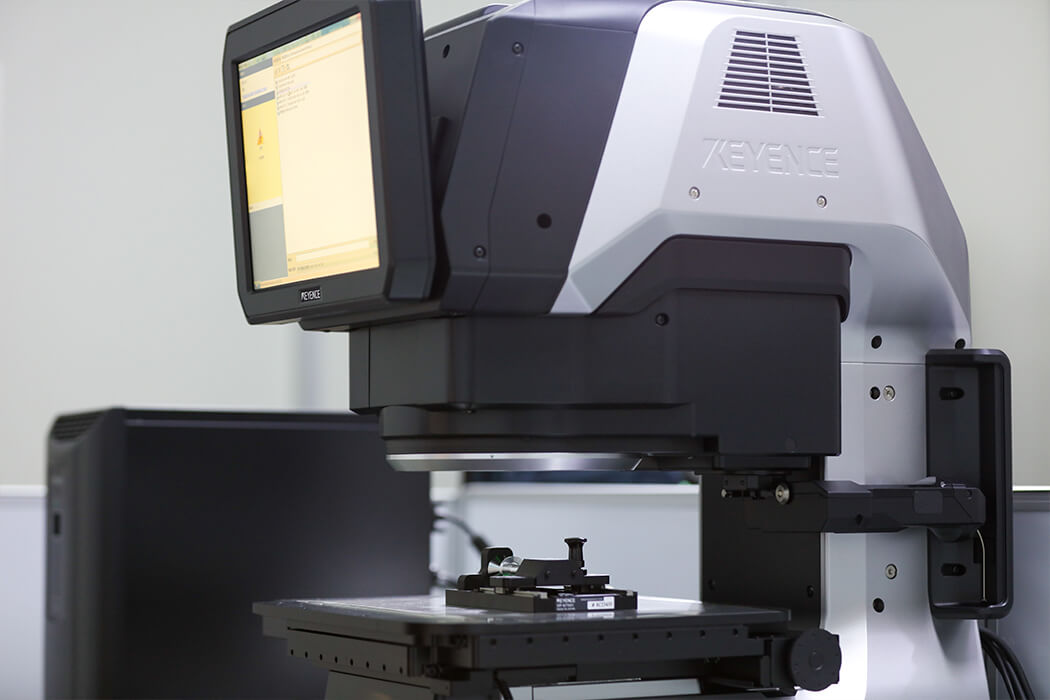

Quality audits are performed throughout our factories and employees. We have adopted the most advanced optical projectors and various electronic measurement instruments such as ZEISS coordinate measuring machines to implement rigorous safeguards for product quality. We perform manufacturing tests with the utmost diligence in every phase of production to ensure that customer commissioned parts processing are completed with the highest precision and quality.